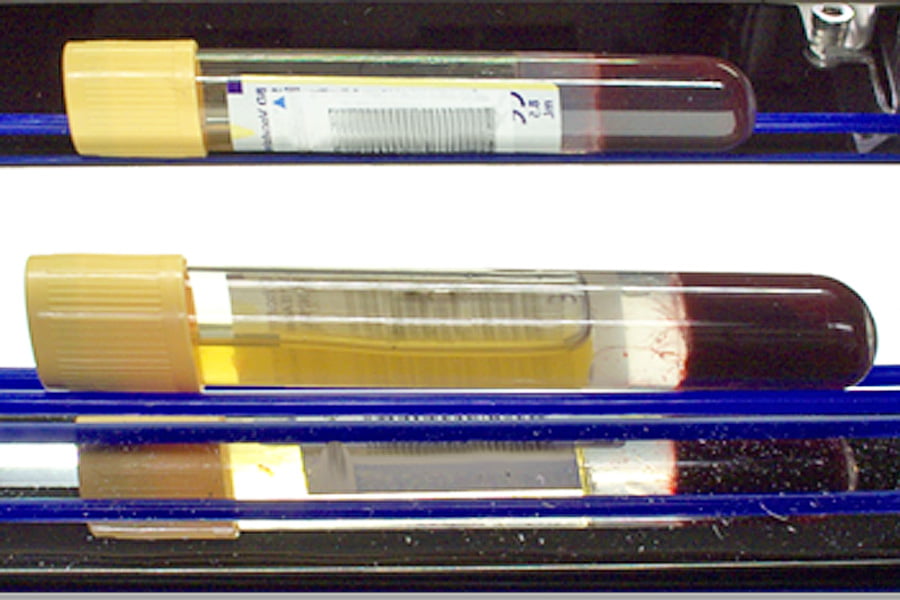

Only completely centrifuged specimen (see figure above) will provide correct results in the analysis. To avoid faulty or failed analyses, a time-consuming and error-prone visual inspection had to be carried out by laboratory personnel in the past. Now the ASP SortPro does this while capturing and sorting the samples.

With its optical detector, SortPro can identify insufficiently centrifuged tubes. This information can be reported to the LIS and/or the affected tube sorted into a separate target compartment.

Take a look at our video:

SortPro detects much more than barcodes and cap colors. Error-free and every second, it can also check the quality of the processed specimen. All the visible features that your laboratory personnel use to identify sample tubes and assign them for further processing can also be recognized by SortPro and used as sorting criteria. With the recognition of tube type, volume and manufacturer, centrifugation status or the complete engagement of the stamps of aspiration blood samples (e.g. Sarstedt), for the first time a sample sorter can also automate central functions in quality management and relieve specialist personnel of further routine tasks.