The all-new ASP SortPro Tube Sorter

Efficient sample registering and sorting

Enhanced precision in sample detection and identification of errors

SortPro Tube Sorter detects a wide range of special materials automatically and saves you time and money. Save time to evaluate, search and identify your samples with comprehensive analysis software. Above all, quickly deliver samples for analysis with the fastest and most reliable sorter available today.

Hassle free customization

A bulk sorter for your laboratory needs!

SortPro Tube Sorter is the only tube sorter capable of assessing the correctness of the samples it handles and thereby minimizes erroneous diagnosis and downtime in analytics due to inaccurate tubes or sample IDs.

SortPro Tube Sorter uses artificial intelligence and advanced computing power to support the work in the accessioning area of your laboratory while remaining easy to operate.

TubeIdent, which is a high definition optical detection unit, is the basis of ASP SortPro’s intelligence, a huge leap forward from other solutions still relying on barcode readers and inaccurate spectrometers.

Barcode

1D up to 16 digits (2D upon request) Code 128, Codabar, Code 39/93, UPC A, Interleave 2 of 5, EAN-13, Code 2 of 5, GS 1 DataBar Omnidirectional / Expanded / Limited

Target compartments with status display

A threecolor LED-band above each target bin displays their respective fill level. Additionally, an e-ink display individually shows a description of which samples are going to that target according to the active sorting rule.

Priority input

Feed in samples directly to priority area on the detection unit bypassing the conveyor belt to rapidly process urgent samples. Simultaneously, the device reports this prioritization to the LIS.

Connectivity to other industry players*

Easy-to-use interfaces enable rapid implementation for data exchange across different platforms.

Hassle-free operation

Removing a target bin is possible at any time, because of the integrated sample buffers, SortPro runs continually without stopping, even if the staff removes a target bin to bring samples to their the next phase.

Bulk sample input

The sample inlet holds hundreds sample tubes. Additionally, laboratory staff can add new samples continuously. The device starts and stops automatically. The system transports the samples to the detection unit quickly and with minimal vibration.

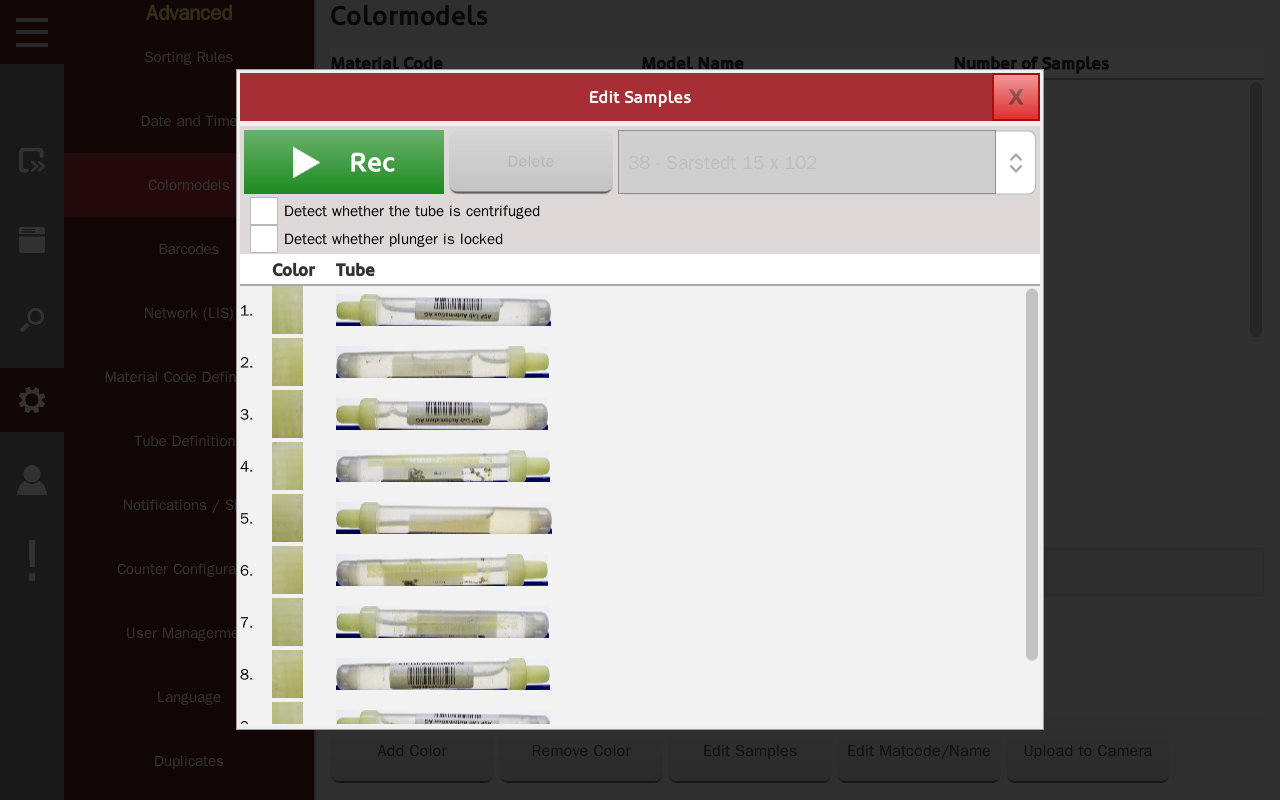

TubeIdent™

TubeIdent enables the detection unit to distinguish samples by cap color, coding ring color (Sarstedt) and tube shape. We can detect up to 64 million unique shades of color, including striped color (tiger caps). We can distinguish length, thickness and shape of all commercially available tube types.

Customization

The fastest Bulk sorter

Free up your staff from distributing and sorting samples!

The ASP SortPro Tube Sorter processes up to 3,600 tubes per hour while identifying all visible features that laboratory staff normally use to identify sample tubes and assign them for further processing. Most importantly, these features are actively used as sorting criteria. For example, this includes the type of tube, manufacturer, centrifugation status or the complete removal of plunger for aspiration blood sampling systems (e.g. Sarstedt). SortPro recognizes much more than just barcodes and cap colors!

Complex laboratory operation? No problem!

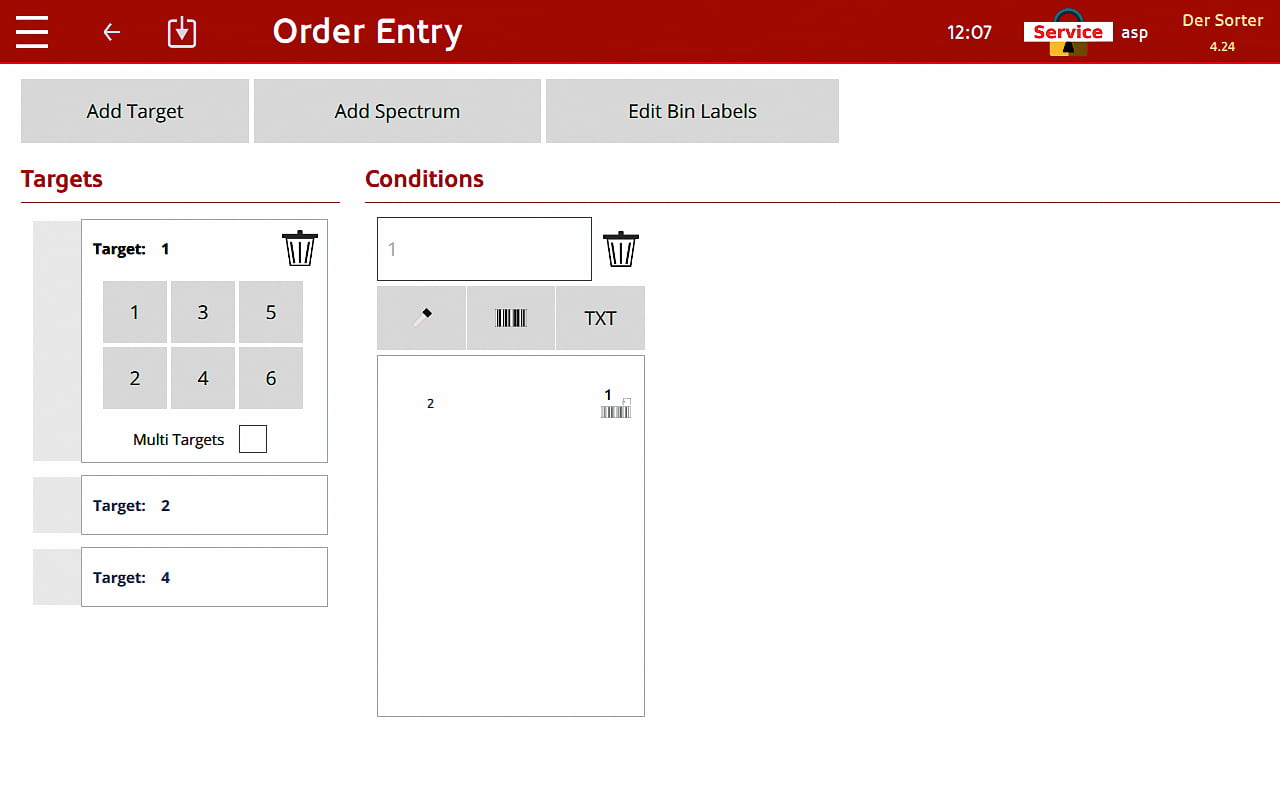

Optimize the workflow as you want with an easy implementation of SortPro Tube Sorter in any medical laboratory environment

SortPro bulk sorter offer individual configuration possibilities for each laboratory environment. Consequently, it adapts to changing laboratory processes at any time!

Your laboratory staff can easily change SortPro Tube Sorter’s sorting rules without the need of extra technical service!

SortPro offers customization possibilities. For example, you can choose between 6 and 16 sorting destinations and adapt it with various aditional options to flawlessly support your laboratory.

SortPro is IVD, LIS and middleware independent. In other words, laboratories can combine it with any existing system. Additionally, SortPro processes all standard cylindrical sample containers.

The optical detector unit can detect any visual coding and features of the samples with a 360˚ Scanner. Therefore, SortPro will detect any subsequent future changes in the features. Unlike other, this would require a simple and secure software update.

Teach in mode

New or updated container types are quickly and easily added/updated to the database by laboratory staff. Specifically, this is done by running a few samples of the new or updated sample type through SortPro Tube Sorter in teach-in mode. As soon as the bulksorter regonizes the sample, it becomes part of the sample type library. Nonetheless, saved sample types are very easy to update, for example, if cap colors undergo slight changes due to different pigment in production process.

SortPro basic unit is very compact, starting at 1.2 m (3.93 ft) wide and 0.6 m (1.96 ft) deep. It weighs only 120 kg (264,55 lb) and requires 250 W electrical load, therefore it is easily installed in any laboratory

Ready to get started?

FAQ

Here you find a selection of the most frequently asked questions

You could not find the answer to your questions ? Do not worry, we will be happy to clarify any doubts you might have about the device. Get in touch with us!

How many samples can I pour into the funnel of the SortPro Tube Sorter?

What is the capacity of samples per target bin?

Do I still need manual sorting alongside the SortPro Tube Sorter?

What is the capacity of samples per target bin?

Will the samples be sorted and distributed rapidly enough?

Sorting and distrubuting up to 3,600 samples/hour, the new SortPro Tube Sorter is extremely agile and the fastest tube sorter on the market.